Introduction to Carbon Fiber

Carbon fiber is a new type of fiber material with a carbon content of over 95% and high strength and modulus. It has the characteristics of high hardness, high strength, light weight, high chemical resistance, and high temperature resistance. At the same time, it also has electrical and thermal conductivity and designability, which can be used to develop more new materials.

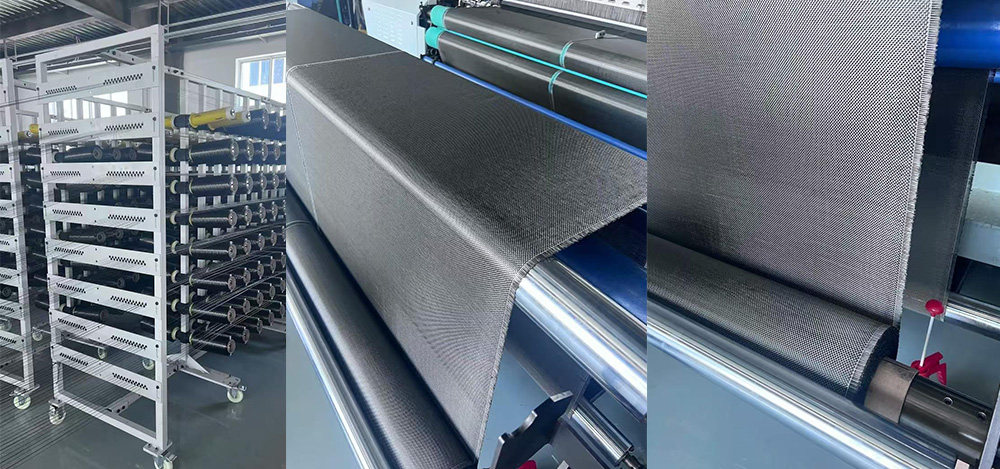

Introduction to Carbon Fiber Weaving Series

Carbon fiber weaving is a forming technology that interweaves continuous carbon fiber bundles into multidimensional structures through specific weaving processes. Its core is to achieve multi-directional fiber arrangement to enhance the multidimensional mechanical properties of composite materials. Here are the performance advantages:

Multi directional bearing capacity

The interwoven structure of warp and weft enables the material to have high strength and modulus in all X/Y/Z directions, and the compressive strength is increased by 40% compared to unidirectional prepreg.

Anti fatigue and impact resistance

Fiber interweaving points disperse stress, resulting in a fatigue life of 3000 hours for drone blades under high-speed rotation; The ballistic energy absorption rate of woven bulletproof vests is increased by 35%.

Adaptability to complex surfaces

Supporting variable angle layering, it can seamlessly wrap irregular surfaces such as car battery box covers (reducing weight by 40%).

|

Carbon fiber woven fabric series -1K, 3K, 6K, 12K |

||||||||

|

Product model description: Fabric 4 warp and weft density and amplitude can be produced according to customer requirements. Among them, FS represents flying plastic, C represents carbon fiber, and W represents woven fabric. |

||||||||

|

model |

Fiber type |

Fabric structure |

fiber density |

Mass per unit |

thickness |

width of cloth |

||

|

|

longitudinal |

zonal |

|

longitudinal |

zonal |

|

|

|

|

FSCW-01-A-120 |

1K |

1K |

plain weave |

9 |

9 |

120 |

0.16 |

100 |

|

FSCW-01-B-120 |

1K |

1K |

twill |

9 |

9 |

120 |

0.16 |

100 |

|

FSCW-03-A-200 |

3K |

3K |

plain weave |

5 |

5 |

200 |

0.3 |

100 |

|

FSCW-03-B-200 |

3K |

3K |

twill |

5 |

5 |

200 |

0.3 |

100 |

|

FSCW-03-A-240 |

3K |

3K |

plain weave |

6 |

6 |

240 |

0.32 |

100 |

|

FSCW-03-B-240 |

3K |

3K |

twill |

6 |

6 |

240 |

0.323 |

100 |

|

FSCW-06-A-320 |

6K |

6K |

plain weave |

4 |

4 |

320 |

0.38 |

100 |

|

FSCW-06-B-320 |

6K |

6K |

twill |

4 |

4 |

320 |

0.38 |

100 |

|

FSCW-12-A-400 |

12K |

12K |

plain weave |

2.5 |

2.5 |

400 |

0.46 |

100 |

|

FSCW-12-A-480 |

12K |

12K |

plain weave |

3 |

3 |

480 |

0.52 |

100 |

|

FSCW-12-B-480 |

12K |

12K |

twill |

3 |

3 |

480 |

0.52 |

100 |

Application scope

The carbon fiber weaving series produced by our company is very suitable for applications that require lightweight, such as aviation, aerospace, automotive, sports equipment, and other fields.

PREV: Carbon fiber weaving series

NEXT: No content available at the moment